A double-ended bolt, as its name implies, features threads at both ends while having an unthreaded rod in the middle that can vary in thickness. It's also referred to as a double-ended screw or stud. This type of bolt is commonly utilized in heavy machinery, such as mining equipment, bridges, automobiles, and gear reducers.

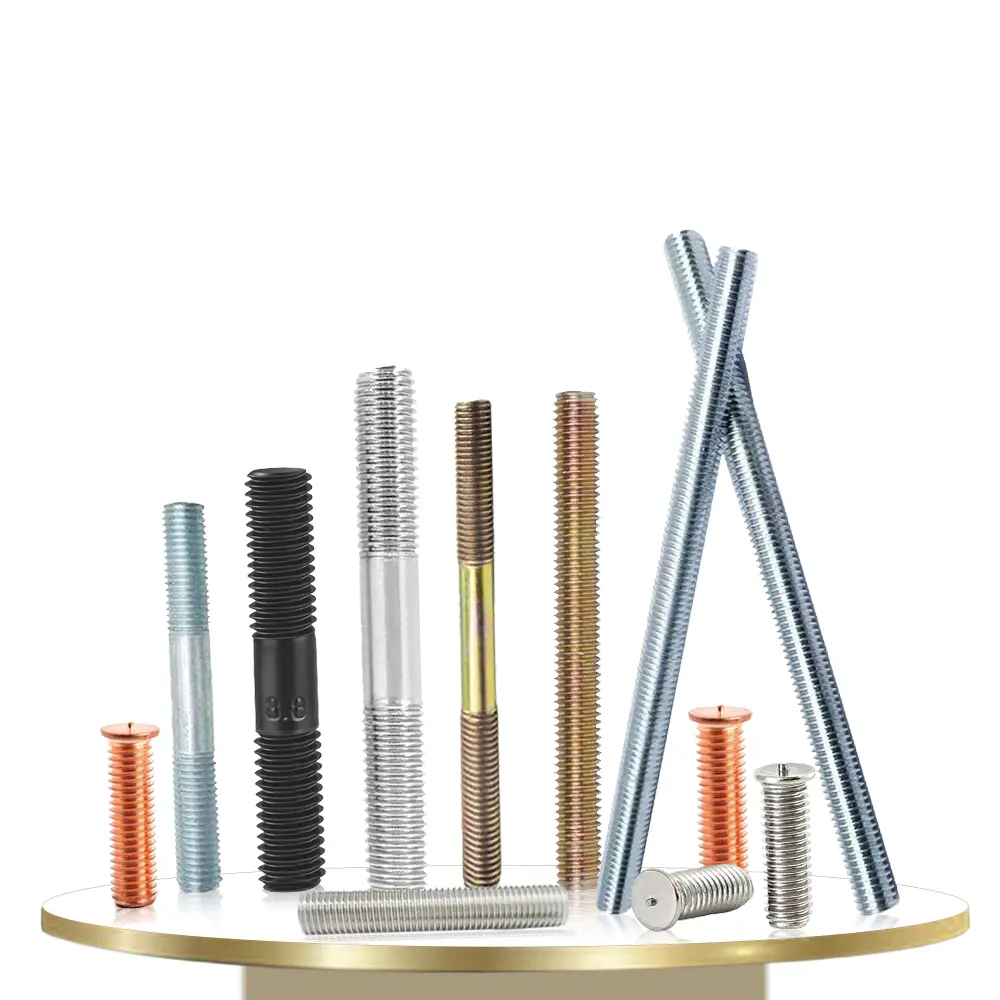

Here's a visual representation of a double-headed bolt:

**In What Situations Are Double-Headed Bolts Used?**

1. **When Connecting Thick Components:** When the thickness of the components being joined is significant and requires a longer bolt, double-headed bolts are typically employed.

2. **For Thick Plates and Hard-to-Access Areas:** These bolts are ideal for joining thick plates or areas where hexagonal bolts cannot be easily used, like in concrete roof trusses, suspended monorail beams, and other similar applications.

3. **Frequent Disassembly Needs:** In large-scale equipment where frequent disassembly is required, and there’s a risk of damaging external threads, double-headed bolts offer a more practical solution due to their ease of disassembly and replacement.

Double-ended bolts are manufactured following standards such as GB897-GB901, using materials like Q235, 45#, 40Cr, 35CrMoA, and Q345D. They come in sizes ranging from M3mm to M100mm, with lengths customizable based on customer requirements.

High-strength double-headed bolts made from materials like 35#, 45#, 35CrMoA, 25Cr2MoV, 304, 316, 304L, 316L, 2H, 2HM, B7, B7M, B16, B8, B8M, and 8M are widely applied in sectors such as power generation, chemicals, oil refineries, valve manufacturing, railways, bridges, steel structures, automotive, and motorcycle components.

**How to Install Double-Headed Bolts?**

1. **Use Lubrication During Installation:** Applying lubricant when installing double-headed bolts prevents them from seizing during insertion and allows for easy removal and reuse later.

2. **Ensure Proper Alignment and Fit:** To maintain secure connections between the bolt ends and the equipment body, it’s crucial that the fastening end of the bolt has a slight surplus diameter at its back center. This can be achieved by using a shoulder design or by tightening the threads at the back end shallowly. If the bolt is being installed into soft material threads, the surplus should be slightly greater.

3. **Maintain Perpendicularity:** The axis of the double-headed bolt must remain perpendicular to the surface of the component. During drilling and tapping, this alignment should be checked using a protractor. If there’s a slight misalignment, a tap can be used to correct the hole. However, if the angle is too large, forcing adjustments could result in bolt damage.

As a leading manufacturer of double-ended bolts, Aozhan Fasteners is dedicated to delivering premium products and exceptional service. Equipped with state-of-the-art machinery and a skilled workforce, we consistently adopt innovative technologies and management practices to uphold consistent quality and timely deliveries. We also prioritize collaborative efforts with clients to tailor solutions to meet their specific needs. For further information about our offerings and services, feel free to reach out to us today. Let Aozhan Fasteners become your go-to partner for all your fastener requirements!

Heshan Janno Kitchen and Bath Technology Co.,Ltd , https://www.janno-ks.com