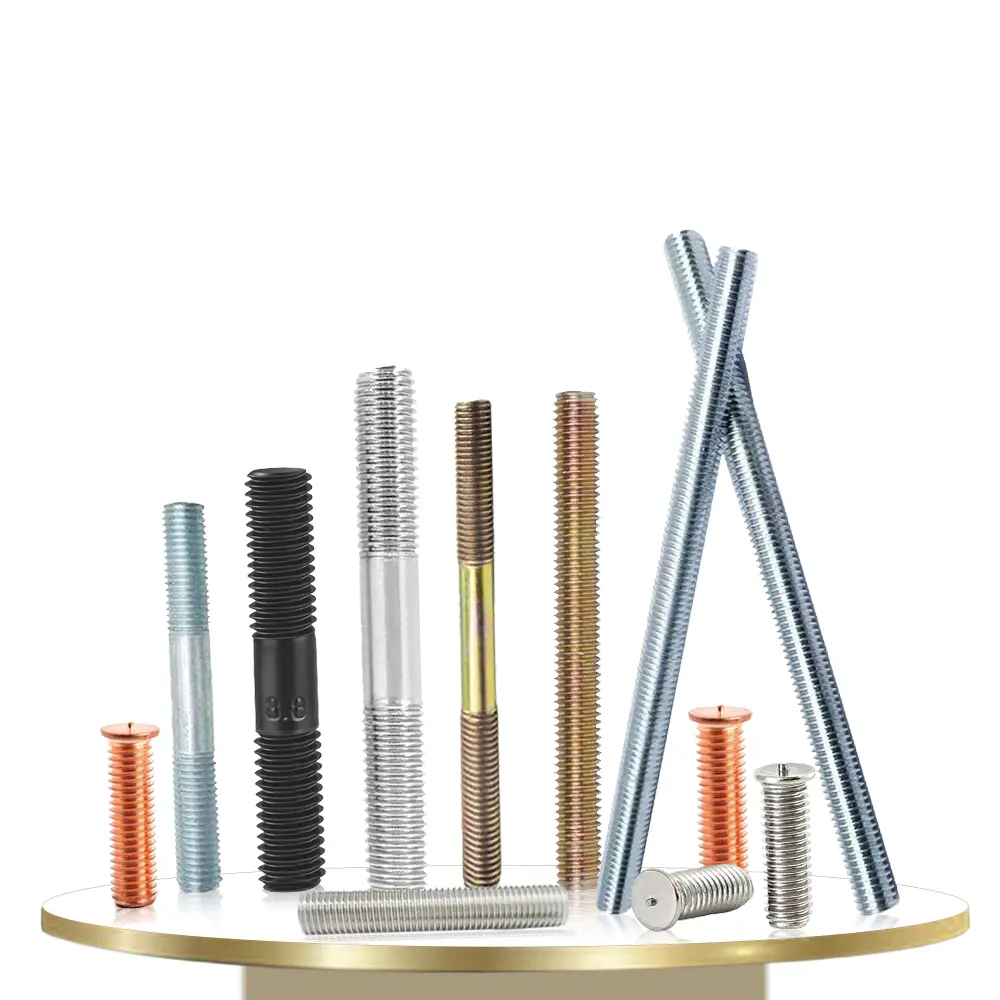

A double-ended bolt, as its name implies, features threads at both ends while having an unthreaded rod in the middle—either thick or thin. It’s also referred to as a double-ended screw or stud. This type of bolt is typically used in large primary equipment like mining machinery, bridges, automobiles, and gearboxes.

### In What Cases Are Double-Headed Bolts Used?

1. **When the Thickness of the Connected Body is Significant:** When the thickness of the connected component is large and requires a long bolt, double-headed bolts are often the go-to solution.

2. **For Thick Plates or Inconvenient Locations:** Double-headed bolts are ideal for connecting thick plates or areas where using hexagonal bolts is impractical, such as in concrete roof trusses or monorail beam suspension components.

3. **Frequent Disassembly Needs:** In large-scale machinery, some connectors may need frequent disassembly. In these cases, double-headed bolts offer a more convenient option since their external threads are less prone to damage during assembly and disassembly.

These bolts are manufactured following GB897-GB901 standards, utilizing materials such as Q235, 45#, 40Cr, 35CrMoA, and Q345D. Specifications range from M3mm to M100mm, with lengths that can be customized based on customer requirements.

High-strength double-headed bolts made from materials like 35#, 45#, 35CrMoA, 25Cr2MoV, 304, 316, 304L, 316L, 2H, 2HM, B7, B7M, B16, B8, B8M, and 8M are widely utilized across industries including power generation, chemical processing, oil refineries, valve manufacturing, railways, bridges, steel construction, automotive, and motorcycle components.

### How to Install Double-Headed Bolts?

1. **Lubrication During Installation:** Apply lubricant when installing double-headed bolts to prevent them from seizing during threading. This ensures smooth installation and removal for future reuse.

2. **Ensuring Proper Fastening:** To guarantee the fastening end of the double-headed bolts aligns snugly with the equipment body threads, the fastening end should have a slight surplus beyond the diameter's center. Options include using a shoulder structure or shallow threading for a few turns at the back. When installing into soft material threads, the surplus can be slightly greater.

3. **Alignment with the Surface:** The axis of the double-headed bolt must remain perpendicular to the surface of the body. Both the bottom hole and tapping process should account for this. A protractor is recommended for verification. If there's a slight tilt, a tap can correct the screw holes; however, excessive tilt cannot be corrected by force, as it risks damaging the bolt.

### About Aozhan Fasteners

As a leading manufacturer of double-headed bolts, Aozhan Fasteners is dedicated to delivering top-notch products and exceptional service. With state-of-the-art equipment and a skilled workforce, we continually adopt innovative technologies and management practices to maintain consistent quality and timely deliveries. We also collaborate closely with clients to tailor solutions to their specific needs.

If you’d like to learn more about our offerings or seek assistance, feel free to contact us today. Let Aozhan Fasteners become your trusted partner for all your fastener requirements!

Brass Bathtub Faucet,Brass Tub Faucet,Brass Roman Tub Faucet,Brass Freestanding Tub Faucet

Heshan Janno Kitchen and Bath Technology Co.,Ltd , https://www.janno-ks.com