What is Underground Drainage?

Alright, so underground drainage is exactly what it sounds like—drainage that operates beneath the surface. It consists of various lengths of pipes and fittings such as bends, junctions, and other components designed to change the direction of the pipe or connect to other systems. Primarily, this system is used to transport wastewater (like greywater) or sewage directly to a sewage treatment plant. Additionally, it can also handle rainwater drainage into soakaways or nearby watercourses.

These days, the most common material for these systems is PVC due to its lightweight yet robust nature, durability, and affordability compared to alternatives like clay or concrete. Its light weight makes installation simpler, and it requires minimal maintenance. The smooth inner walls of PVC pipes enhance the flow efficiency of wastewater, offering better flow rates than clay or concrete pipes.

Identifying an underground drainage system is straightforward—it’s typically terracotta in color, which is the industry standard. Interestingly, soil pipes and fittings are virtually identical to drainage pipes, except they are usually black, white, or gray and contain UV additives to prevent discoloration from sunlight exposure.

How do you install underground drainage?

First, trenches must be dug to the correct "fall" to use gravity to move the wastewater efficiently. Pea shingle (usually 10mm or 20mm) should be laid at the bottom of the trench to protect the pipework. Proper planning is essential to allow for future rodding, testing, cleaning, and inspection of the system. Typically, an experienced drainage engineer will plan the layout with an architect's input, but smaller projects can be handled by groundworkers or general builders as long as they adhere to the Approved Document H guidelines.

The fittings and pipework are quite easy to join. They usually feature a "push-fit" mechanism where pipes come with sockets containing rubber seals, and fittings have either a spigot (to fit into another pipe/socket) or a socket (to accept a spigot).

How do I cut and join the pipework?

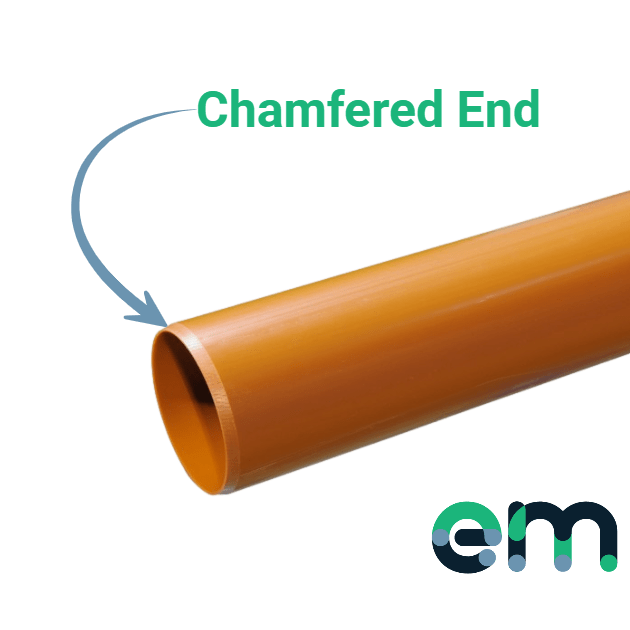

Cutting the pipe is straightforward using a hacksaw or fine-toothed saw, but this leaves a rough or sharp end. If left untreated, pushing the cut end into a socket might damage the seal, leading to leaks—especially problematic with foul water. To avoid this, chamfer the pipe using a chamfer tool to smooth and file down the end. Lubricate the seal in the socket with proper pipe lubricant, then push the pipe firmly into the socket until it stops. Pull it back 10mm to allow for movement and expansion—job done! This method is much easier than working with clay or concrete systems.

How to lay the underground pipes?

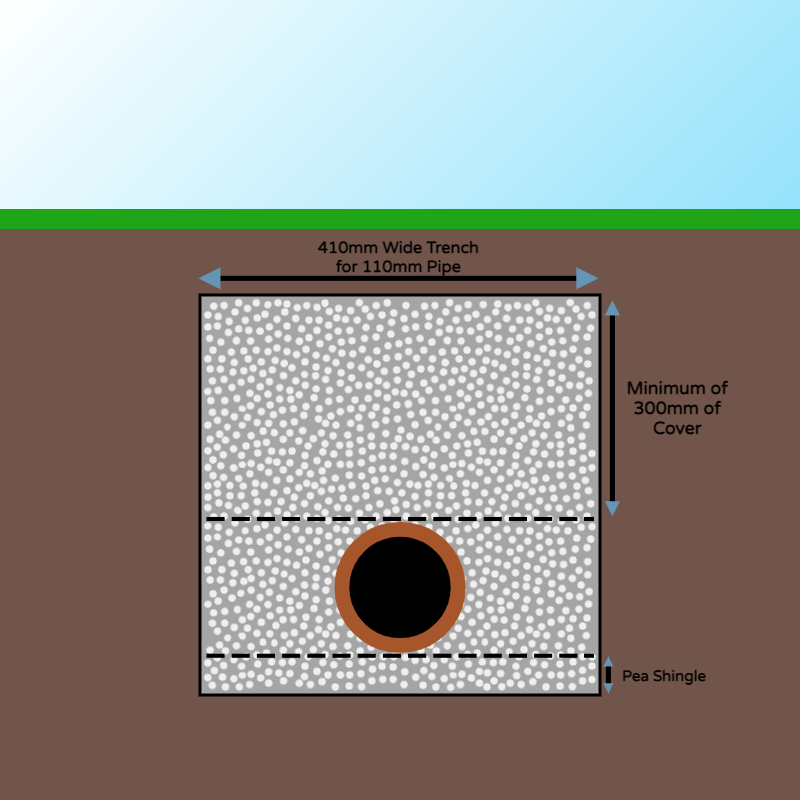

The best practice involves digging a trench, laying pea shingle (10mm/20mm) at the bottom, placing the drainage pipe over it, and filling the trench with more pea shingle for backfill and side fill. This protects and supports the pipework while allowing for expansion and ground movement. For 110mm drainage pipes, the trench should be 410mm wide, and for 160mm pipes, it should be 460mm wide. Always ensure the trench is 300mm wider than the pipe to be laid. While you can use the excavated soil as backfill instead of pea shingle, it needs to be screened for large stones or rocks and isn't as protective.

Buried pipework should have a minimum of 300mm of cover to avoid damage during soil compaction. If certain areas are prone to future excavation, it's wise to place a paving slab over the pipe to shield it from tools like shovels or spades. Warning tapes labeled "Caution: Sewer Pipe Below" can also be installed to alert anyone digging nearby.

How does it connect to the above ground system?

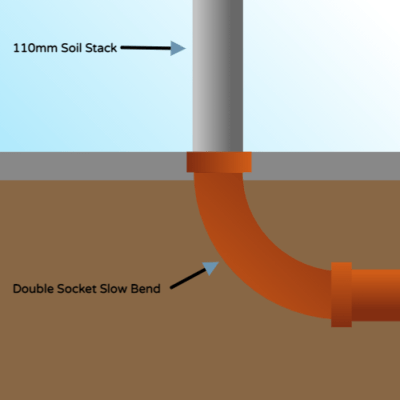

As mentioned earlier, soil pipe systems (the 110mm black, white, or gray pipes running down the side of the house into the underground system) are nearly identical, even manufactured using the same machinery. The cutting and joining processes are identical, and no special adapters are usually needed.

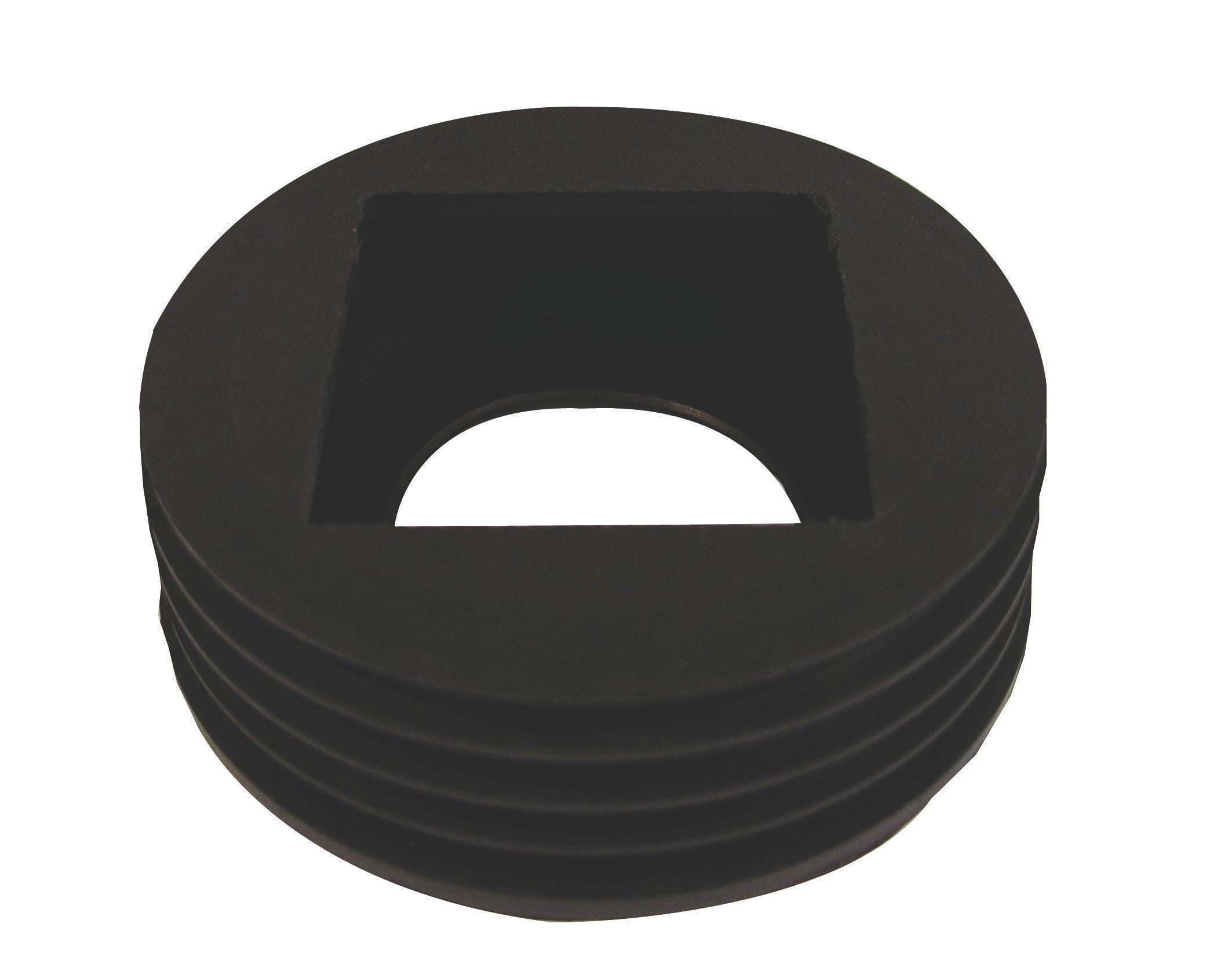

Rainwater pipes or waste pipes are slightly different in size. For rainwater downpipes, a rubber rainwater adapter is necessary. Push this into the 110mm underground pipe and then insert the downpipe. This adapter can also be used for waste pipe systems, though they are typically connected to the 110mm soil pipe higher up the run. Other colored PVC adapters are available to match the downpipe.

What fittings are commonly used in the underground drainage system?

- Underground Drainage Pipe – Available in 3m or 6m lengths with sockets for easier connections without additional couplers or joiners.

- Drainage Pipe Bends – Used to change the direction of the pipe run. Available in various angles from 11.25 to 90 degrees. Some have single sockets (spigot on one end, socket on the other), while others have double sockets. Adjustable bends are also available for tricky angles.

- Drainage Pipe Couplers – Also known as joiners, these connect two lengths of pipe. Single socket versions are available for adapting to solvent systems, and slip couplers are another option.

- Drainage Pipe Junctions – Allow splitting or combining pipe runs. Available as T junctions (90-degree turns) or Y junctions (45-degree turns), with double or triple sockets.

- Bottle Gullies – Feature a grill on top to accept rainwater downpipes or waste pipes. They include a built-in trap to prevent smells and gases from entering the building.

- Underground Drainage Hoppers – Similar to gullies, these allow downpipes or waste pipes into the underground drainage system but lack a built-in trap.

- Lowback P Traps – Installed using hoppers to create a trap preventing foul-smelling gases from entering the property.

- Rodding Eyes – Installed to allow clearing of blockages via rodding.

- Universal Rainwater Adaptors – Rubber adapters enabling connection from rainwater downpipes to the underground system.

- Manhole Bases, Risers, and Lids – Manhole bases enable multiple property connections to converge into a single run leading to the main sewage system. Often installed at the end of driveways before entering roads.

Invert levels and falls in underground drainage:

Typically, 110mm drainage pipes are laid with a fall of at least 1 in 40. This is common for setups involving five or fewer houses, ensuring sufficient flow to minimize blockages. The same principle applies regardless of the manufacturer or brand. For more detailed information, refer to the Approved Document H – Drainage and Waste Disposal. If in doubt, consult a drainage engineer or your local authority.

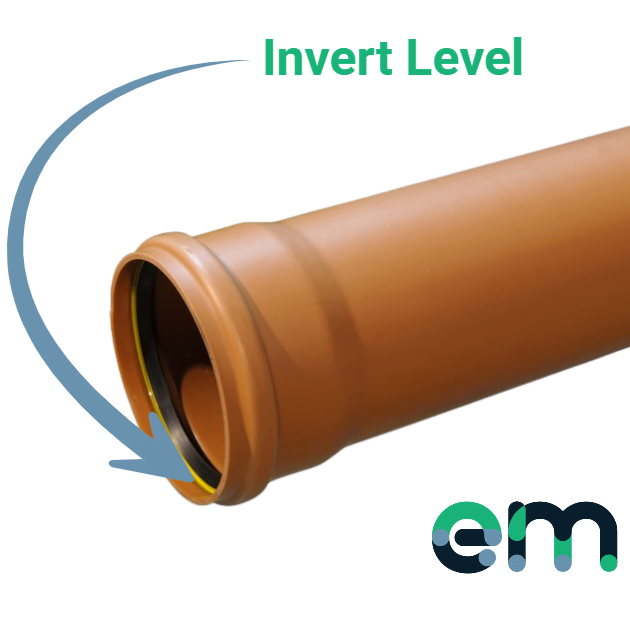

What does invert level mean?

The "invert level" refers to the level of the bottom of the drainage pipe or manhole base outlet. This is the point where the water flows. On architectural or engineering drawings, the invert level is often mentioned alongside the cover level. The invert level indicates the lowest point inside the pipe where water runs. The cover level simply refers to the finished ground level, which can be remembered as the location of the manhole cover. To calculate the invert depth, subtract the invert level from the cover level. For instance, if the cover level is 50 and the invert level is 45, the result would be 5. (50 - 45 = 5). These calculations are crucial for the proper design and function of the drainage system.

What are the falls and gradients for underground drainage?

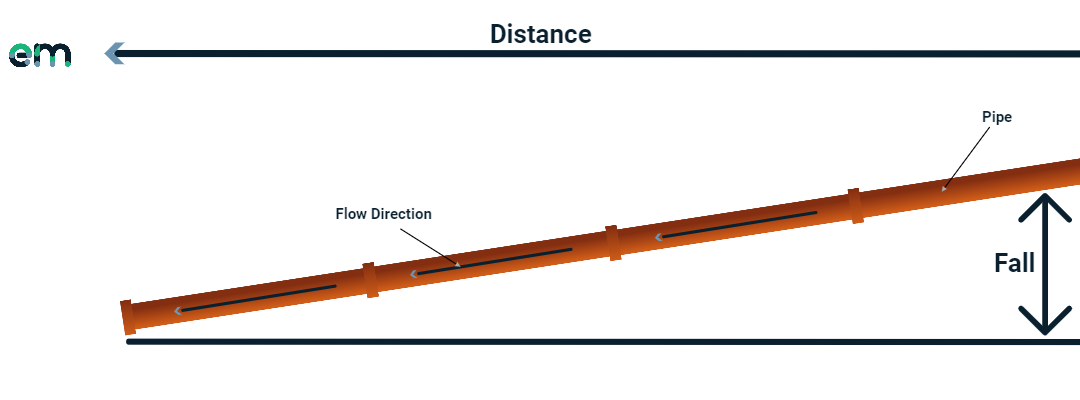

The "fall" refers to the slope of the pipe. A proper fall is necessary to allow gravity to move the wastewater along the pipe. Technically, the fall represents the vertical drop of the pipe along its horizontal length. Calculations must be performed to determine the correct fall for optimal flow rates and to prevent blockages caused by solids or waste. The fall is the vertical distance the pipe drops from its starting point to its endpoint.

A common fall is 1 in 40, meaning for every 40 units of pipe length, the pipe drops by one unit. For a 40-meter run, the end of the pipe will be 1 meter lower than the start. The unit of measurement (meters, centimeters, inches, etc.) doesn't affect the proportion or effect of the fall.

Occasionally, the term "gradient" is used (though less frequently these days). To calculate a gradient, divide the vertical fall by the horizontal length of the pipe run. In our 1 in 40 example, the calculation would be (1 divided by 40), resulting in a gradient of 0.025. See the illustration below for clarity.

The gradient equals the fall distance

For instance, in a 24-meter section of drainage pipe with a fall of 0.30 meters, the gradient would be calculated as follows:

- Gradient = 0.30 divided by 24

- Gradient = 0.0125

This can be expressed as a ratio: 1 in 80.

- Gradient = 1 / 0.0125 = 80

- Fall = 1 in 80

The formula can also be rearranged to calculate the fall if the gradient is known:

The fall is the gradient multiplied by the fall distance

For example, calculate the fall in a 50-meter section of foul water pipework with a gradient of 1 in 80. First, convert the gradient to a decimal: 1 / 80 = 0.0125.

Fall = Gradient x Distance

Fall = 0.0125 x 50

Fall = 0.625 meters or 625mm.

Adapting to other materials

PVC drainage can be adapted to clay or cast iron pipes using rubber pipe connectors featuring a jubilee clip to adjust for different wall thicknesses.

How and when to test the drains?

Although local approval authorities may vary, the Approved Document H – Drainage and Waste Disposal provides guidance on testing procedures.

What is an OD / ID?

This refers to the outside diameter and inside diameter of the pipe. To connect or adapt to the pipe, the OD is the critical measurement. To calculate flow rates, the ID is used. Subtracting the inside diameter from the outside diameter gives the wall thickness of the pipe, while the inside diameter determines the space within the pipe. The outside diameter indicates the overall width of the pipe, helping determine the size of the hole needed for drilling, etc.

Can I buy this stuff from EasyMerchant?

Absolutely! And you won't find it cheaper elsewhere! We purchase in bulk quantities, allowing us to secure large discounts that let us offer these products at the same prices as national contractors. Check out our underground drainage range here. We offer two brands: Brett Martin, a well-known choice for those who prefer quality, and an eco-friendly option that performs just as well at a more affordable price.

As always, thank you for reading our guide here at EasyMerchant. If you have further questions about underground drainage installation, feel free to call me at 01371 850 120 or email me.

Author Bio

Nathan Wilde

Nathan has over 12 years of experience in the drainage and plastics industries. Having worked for both builders' merchants and major manufacturers, Nathan brings extensive industry and product knowledge. At EasyMerchant, he dedicates himself to simplifying tradespeople's lives.

Shop Underground Drainage

110mm Drainage Pipe Fittings

110mm 3m Single Socket Underground Drainage Pipe

110mm Drainage Pipe Coupler

110mm Underground Drainage Pipe Junction

Today, glass cistern has become one of the most popular products in the bathroom products market. The design of the glass Toilet Tank is made of high-quality glass materials, and the appearance is beautiful and generous, which can add a high-end and fashionable atmosphere to the bathroom and become a beautiful landscape in the bathroom space.

In addition to the exterior design, the performance and functionality of glass toilet tanks are also noteworthy. The glass material has the characteristics of anti-corrosion, wear resistance, and easy cleaning. It can resist the corrosion of chemical substances and is not easily damaged by external forces. At the same time, it can be easily cleaned and has a long service life. The glass toilet water tank can also be applied to various water qualities, and will not be damaged due to the difference in water quality, which ensures the long-term use of the toilet water tank.

Glass toilet cisterns also offer advantages when it comes to installation and maintenance. Due to its lightweight design, it does not require too much support and can be installed more easily and conveniently. And because of the material properties, it can be easily cleaned and maintained, making toilet tank maintenance even simpler.

In short, the glass cistern has become an indispensable part of the modern bathroom space due to its beautiful appearance, strong material and easy maintenance. It is not only practical, but also can improve the sense of class of the entire bathroom space, and has become a popular product in the bathroom industry.

Glass Cistern, Glass Toilet Tank, Glass Cover Toilet Cistern, Glass Toilet Cistern

Guangdong Fabia Intelligent Technology Co., Ltd , https://www.smartfabiatoilet.com