Introduction: TFL Insulated Bearings – The Future of Motor Protection

Bearing galvanic corrosion occurs when the surface of the bearing is exposed to shaft currents during motor operation. These shaft currents are primarily generated due to voltage fluctuations and electromagnetic interference at the frequency converter's output, which exposes the bearings to high-frequency voltages, thereby causing galvanic corrosion. Insulated bearings, a specialized type of bearing, play an indispensable role in motor protection due to their excellent insulating properties. As modern industrial applications demand higher reliability and efficiency, insulated bearings, particularly those from TFL, are becoming increasingly significant in industries like power generation, petrochemicals, and mining.

TFL Insulated Bearings, Inc.

Since its inception, **TFL Insulated Bearings** has been committed to advancing the latest insulated bearing technologies. With over a decade in the bearing industry and more than eight years of experience in international trade, we have built a reputation for excellence. Our product range includes low-noise, low-vibration bearings with high rotational accuracy and excellent sealing performance. Available in sizes ranging from 1mm to 200mm, our bearings cater to diverse industrial sectors. Among numerous Chinese bearing manufacturers, we stand out due to our technical expertise, adaptability, innovation, and relentless R&D efforts.

TFL Insulated Bearings Catalog

As an ISO-certified manufacturer of insulated bearings in China, TFL Insulated Bearing Co., Ltd. offers competitive pricing, maintains a stock of 1 million insulated bearings, and ensures delivery within 7 days. We are agents for leading brands such as SKF, KOYO, and NTN. Our product lineup includes ball bearings, angular contact bearings, spherical roller bearings, cylindrical roller bearings, needle roller bearings, tapered roller bearings, precision bearings, bushings, thrust bearings, linear bearings, single and double row bearings, as well as inch bearings.Customer reviews for TFL Bearings

"I just wanted to express my gratitude for the professionalism of your sales team and the exceptional customer service provided by Eugene. Since I’ve been working with TFL Bearings, Eugene has consistently responded promptly to my inquiries, and we appreciate the competitive prices he offers." —Elton Don, ModernMushroom Farms "My name is Tim, and I’m from Somalia. This is my fourth year with TFL Bearings, and I’ve become the top seller of bearings in my local area. Thank you for your consistent supply, especially the OEM-bearing products, which are very popular in Somalia." —Russel Drou, ArchitectTFL Insulated Bearing Warranty

At TFL Insulated Bearings, we are committed to combating counterfeits and maintaining transparency. We collaborate exclusively with leading original manufacturers in the bearing field. Every penny of our customers' money matters to us, and we strive to provide the best service while maximizing value. Offering the same product at the lowest price remains our long-term motivation and driving force for business growth.Core Technology of TFL Insulated Bearings

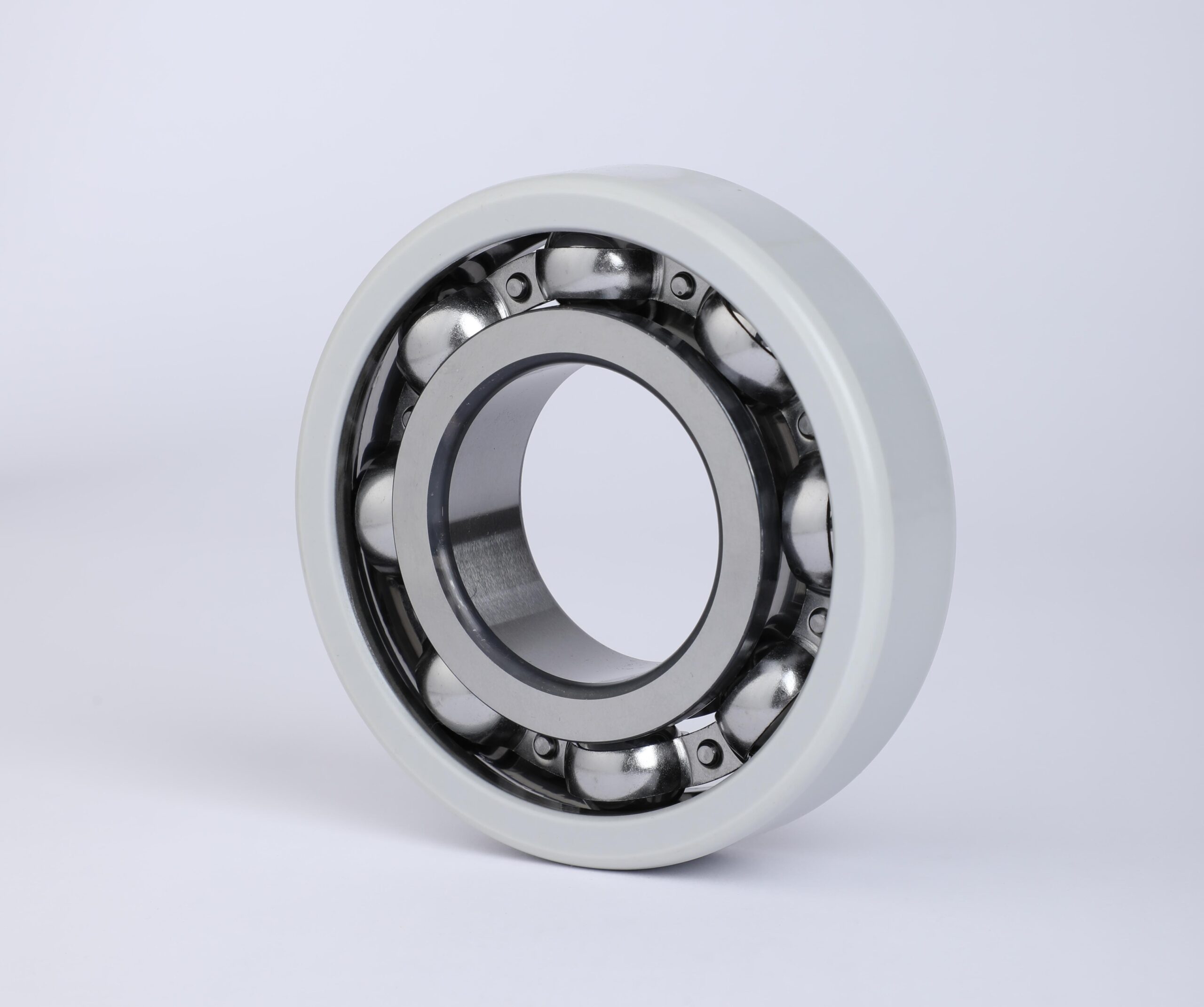

Insulated bearings prevent the flow of electric current and possess inherent insulating properties. TFL insulated bearings leverage specific materials and processes to enhance insulation performance, broadening their range of applications. These bearings not only meet basic performance requirements such as pressure, speed, and durability but also effectively isolate external current interference, ensuring equipment safety and reliability.

TFL Ceramic Coating Technology: Key to Insulation Performance

Ceramic coatings refer to a category of inorganic non-metallic coatings composed of materials like oxides, carbides, and nitrides. Common oxide ceramics include Al₂O₃, TiO₂, and ZrO₂; carbide ceramics include SiC and WC; nitride ceramics include Si₃N₄ and TiN. These materials are applied to metal or other substrates via techniques such as fusion burning, spraying, or vapor-phase deposition to impart new properties to the substrate.Hybrid Ceramic Design: Balancing Insulation and Durability

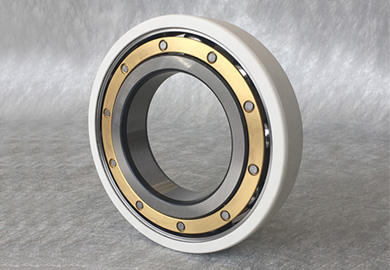

Advantages of TFL hybrid ceramic bearings: • Maximum current protection through insulation • Higher speed suitability due to lower centrifugal forces from lighter rolling elements • Reduced weight—Silicon nitride is 60% lighter than traditional steel rolling elements • Extended life with longer relubrication intervals • Lower friction, especially at high speeds, reducing frictional heat • Increased stiffness with less deformation in the rolling contact area • Mitigates risks of poor lubrication at high speeds or rapid acceleration • Interchangeable sizes requiring no additional tools Characteristics of ceramic rolling elements: 1. Electrically isolating 2. Low friction coefficient 3. Corrosion resistant 4. Higher modulus of elasticityOptimized Dielectric Strength: Ensuring Long-term Reliable Operation

The optimized dielectric strength of insulated bearings is primarily determined by the thickness of the insulating layer and the choice of material. Thickness of the insulating layer: Insulated bearings typically have a 50-200μm thick ceramic coating on the bearing surface, capable of withstanding electric arcing generated by 1000V voltage. Thicker coatings can handle even higher voltages, such as discharges above 1000V. Selection of insulating materials: Insulated bearings usually use oxide ceramics as insulating materials, which offer excellent insulating and corrosion-resistant properties. Additionally, the design of insulated bearings considers factors such as bond strength, thermal effects, and sealing technology to ensure the durability and insulating properties of the coating.Application Areas of TFL Insulated Bearings

The primary application areas for insulated bearings include the power sector, railway infrastructure, industrial pumps, high-speed spindles, and the electric vehicle industry.

Electric Vehicles: Enhancing Powertrain Efficiency

In electric vehicle motors, insulated bearings effectively reduce insulation losses and failure rates. During operation, the potential difference between the stator and rotor generates current that flows through the bearings, causing galvanic corrosion. The use of insulated bearings blocks this current and prevents corrosion. Furthermore, insulated bearings can endure high temperatures and pressures, reducing motor vibration, wear, and failure rates.Wind Power Generation: Tackling Harsh Environment Challenges

In wind turbines, insulated bearings are critical components, especially in the transmission systems of the motor. They effectively resist high-voltage currents and large shocks while reducing vibration and noise generated by the bearing. The superior qualities of insulated bearings ensure the wind turbine operates efficiently. Without insulated bearings, electrical issues could cause the turbine to shut down during operation.Industrial Pumps and Motors: Improving Reliability and Lifespan

Insulated bearings are also extensively used in construction machinery, such as excavators, loaders, and road rollers, which often operate in dusty, muddy, or wet environments. Without insulated bearings, contamination from water or mud could reduce bearing life, efficiency, and reliability. Insulated bearings help maintain high performance in harsh conditions.

High-speed Spindles: Reliable Partner for Precision Machining

For high-speed spindles, insulated bearings are commonly applied in electric motors and generators, especially inverter motors. During operation, inverter motors generate shaft voltages that, if left unchecked, can cause galvanic corrosion on the bearing raceways and rolling element surfaces, shortening their service life. Insulated bearings block the current path, ensuring more reliable motor performance.Railway Traction: Ensuring Reliability in Long-distance Transportation

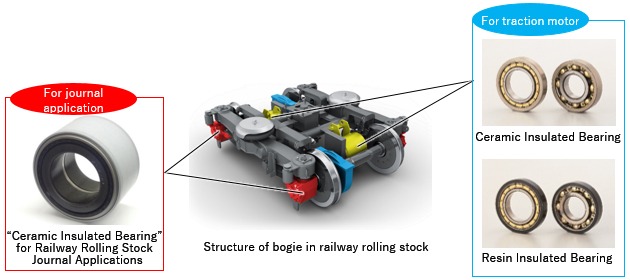

In the railway industry, insulated bearings are primarily used in traction motors for diesel locomotives. These systems often handle high power and voltage, and insulated bearings prevent current damage to the bearings, ensuring normal equipment operation. They also prevent current from affecting the lubricating grease and rolling elements, thus extending bearing life. This is vital for the safe and stable operation of railway infrastructure.Performance Advantages of TFL Insulated Bearings

The outstanding performance of TFL insulated bearings is evident in their excellent load-carrying capacity, superior temperature resistance, low noise operation, and extended service life. These features significantly enhance equipment reliability.

Excellent Insulation Properties: Improved Equipment Reliability

Insulated bearings isolate current and prevent its impact on the bearings, safeguarding equipment operation. By ensuring long-term and stable operation, they dramatically improve equipment reliability. The ceramic coating of insulated bearings exhibits excellent insulating properties, preventing galvanic corrosion caused by induced currents, thus extending bearing life. Some insulated bearings use ceramic rolling elements made of Si3N4 material, which are highly wear-resistant and require minimal lubrication, making them ideal for high-speed, low-friction, and low-temperature operations.Excellent Temperature Resistance: Adapting to Extreme Environments

Regarding high-temperature resistance, insulated bearings are manufactured using special process parameters to rapidly cool and solidify molten particles on the bearing rings, keeping the surface temperature around 100°C. This high-temperature resistance allows the bearings to operate stably in extreme conditions, making them suitable for high-voltage large motors, variable frequency motor-driven equipment, electric vehicles, railroad locomotive traction motors, wind turbines, and other demanding environments.Low Noise Operation: Enhancing Equipment Comfort

Insulated bearings are designed for optimal performance and precision manufacturing, resulting in excellent quiet operation. This design significantly reduces bearing noise at high speeds, enhancing equipment smoothness and comfort. Additionally, the damping effect of grease plays a crucial role in reducing noise. Grease dampens vibrations, minimizing noise generation.

Extended Service Life: Reducing Maintenance Costs

The special materials and manufacturing processes of insulated bearings provide superior high-temperature and corrosion resistance. They can operate reliably even in harsh environments, extending equipment life. Insulated bearings reduce equipment failures and repair costs due to bearing damage, minimizing downtime and maintenance expenses.High Energy Efficiency Design: Ideal Choice for Energy Saving and Environmental Protection

The energy-efficient design of insulated bearings truly contributes to energy savings and environmental protection. By preventing current from passing through, insulated bearings avoid equipment damage caused by current erosion. This reduces maintenance costs and energy consumption, aligning with energy-saving and emission-reduction goals.Selecting and Maintaining TFL Insulated Bearings

Choosing the right insulated bearing is crucial for protecting equipment and boosting productivity. Proper maintenance is equally vital to extend bearing life and improve reliability.

Choosing the Right TFL Bearing Model for Your Application

When selecting the right TFL insulated bearing, consider the following: • Insulation performance: The most important feature of insulated bearings is their insulation performance, including insulation resistance and withstand voltage. TFL insulated bearings typically use a plasma-spraying process to coat the inner or outer ring with a 100μm-thick insulating layer, capable of withstanding at least 1000V voltage to prevent galvanic corrosion. • Size and accuracy: Different sizes and accuracies are required depending on the application scenario. TFL insulated bearings come in a variety of sizes, including: • Deep groove ball bearings: Inner diameter 40mm–140mm, outer diameter 80mm–300mm, width 18mm–62mm. • Angular contact ball bearings: Inner diameter 40mm–140mm, outer diameter 80mm–300mm. • Load-carrying capacity and life: TFL insulated bearings have a long service life since they are not prone to damage from overcurrent and exhibit high operational reliability.Installation Considerations: Ensuring Optimal Performance

Caveats: 1. Do not hit the bearing surface directly with a hammer during installation. 2. Avoid using bearings with damaged insulation surfaces. 3. Clean the bearing housing and bearings, ensuring no conductive substances adhere to them. 4. Select appropriate shoulders to prevent current from flowing through the side of the bearing. 5. The bearing housing should have at least a 0.5mm slope at a 10–15° angle. 6. For DC motors, ground the shaft during resistance testing.Daily Maintenance Tips: Extending Service Life

Routine maintenance of TFL insulated bearings: • Lubrication: Use the following methods for TFL insulated bearing lubrication: - High-pressure oil pump lubrication: Inject lubricant into the bearings via nozzles, suitable for high-speed bearings. - Circulating oil lubrication: An oil pump circulates filtered oil to the bearing interior, cooling and filtering the lubricant for reuse. Suitable for bearings with high rotational speeds. - Oil bath lubrication: Part of the bearing is submerged in an oil bath, and the lubricant is carried upward by the rotating parts and flows back into the oil bath. • Cleaning and inspection: When inspecting a removed bearing, photograph its appearance, confirm the remaining lubricant quantity, and sample the lubricant. When cleaning the bearings, first remove grease or adhesive with coarse washing, then carefully clean with fine washing using neutral water-free diesel or kerosene as the cleaning agent. After cleaning, immediately apply rust preventive oil or rust preventive grease to the bearings.Performance Monitoring: Timely Identification of Potential Problems

Insulated bearings are tested for: 1. Appearance inspection: The most basic test method involves checking the bearing surface for flatness, cracks, rust, damage, etc., to ensure no obvious quality issues. 2. Insulation performance testing: One of the critical parts of insulated bearing testing involves using equipment like multimeters or insulation resistance testers to measure the insulation resistance value. Generally, the insulation resistance should exceed 100MΩ; otherwise, the bearing must be replaced. 3. Noise testing: This method checks whether the bearing sealing cover and bearing cap are intact and sealed properly. Use a sound level meter to measure noise levels when the bearing is running. If the noise is excessive, check if the sealing cover or cap is loose or damaged. 4. Lubrication testing: This method detects bearing lubrication. Check the oil level and quality of the bearing, whether the oil filling port is normal, and whether the lubricant meets the requirements. If poor lubrication is detected, add lubricant or replace it promptly.Conclusion

As industrial technology advances and equipment reliability demands grow, the range of applications for insulated bearings will continue to expand. In the future, TFL insulated bearings will innovate in materials, processes, and technologies to meet higher insulation standards and broader application scenarios. In summary, TFL insulated bearings play a pivotal role in ensuring the safe operation of motors and other equipment, extending equipment life, and improving reliability. With technological advancements and expanding applications, the market outlook for TFL-insulated bearings is promising.Frequently Asked Questions

1. What are TFL insulated bearings used for? TFL insulated bearings are mainly used in the power industry, railroads, machinery and metallurgy, mining machinery, petrochemicals, and other major machinery and equipment industries. 2. How do TFL insulated bearings perform in high temperatures? The performance of insulated bearings in high temperatures depends on their material properties and design. Insulated bearings use a ceramic coating on the bearing surface, which typically has high thermal stability and temperature resistance. The ceramic coating thickness is generally between 50–200 μm, capable of withstanding electrical jump fires at 1,000 V. Thicker coatings can handle even higher voltages. 3. What is the lifespan of TFL insulated bearings? The service life of insulated bearings is typically between 10,000 and 25,000 hours. Factors influencing their lifespan include operating environment, load, and rotational speed. With proper use and maintenance, the life of an insulated bearing can be significantly extended. 4. Can I use TFL insulated bearings in outdoor applications? TFL insulated bearings are perfectly suited for outdoor applications. As a special bearing type, they offer excellent insulating properties that prevent damage from electric current passing through the bearing, adapting to harsh environments. They are widely used in various industrial settings, including outdoor environments with high temperatures, humidity, and corrosive conditions. 5. How can I contact TFL for purchases? To purchase TFL insulated bearings, you can call, send an email, or visit our official website or Alibaba shopping site for consultation. Call Us: 0086 15806631151 Email Us: sales@tflbearing.com URL: https://tfl-bearing.en.alibaba.com/productgrouplist-806672581/Cylindrical_Roller_Bearing.htmlExpanded Reading

Introduction to Insulated Bearings An insulated bearing blocks the passage of electric current and possesses insulating properties. It serves as a protective barrier against electrical damage, assuming critical functions in industrial applications. Insulated bearings are categorized into several types, each tailored to specific needs.Types of Insulated Bearings: Enhancing Electrical Protection in Industrial Applications

Different types of insulated bearings cater to diverse industrial needs, such as deep groove ball bearings, angular contact bearings, and hybrid ceramic bearings. Each type offers unique advantages, such as enhanced durability, improved insulation, and resistance to extreme conditions.Wall Fountain,Waterfall Fountain,Waterfall Feature Fountain,Curtain Water Fountain

Guangzhou Dewy water fountain Technology Co., LTD , https://www.dewyfountain.com