Introduction: TFL Insulated Bearings – The Future of Motor Protection

Shaft currents in electric motors can cause bearing corrosion, which leads to equipment failure and costly repairs. TFL insulated bearings, with their unique ceramic coatings and hybrid designs, offer superior insulation and durability, making them a game-changer in motor protection. These bearings are increasingly popular in industries like automotive, wind energy, and industrial machinery.

TFL Insulated Bearings, Inc.

TFL Insulated Bearings is a global leader in the production of advanced insulated bearings. Established over 10 years ago, we have built a reputation for excellence in the bearing industry. Our products are trusted by customers worldwide, thanks to their superior quality and performance. We specialize in creating bearings with low noise, low vibration, high rotational accuracy, and excellent sealing properties. Our product line includes ball bearings, angular contact bearings, spherical roller bearings, cylindrical roller bearings, needle roller bearings, tapered roller bearings, and more.

TFL Insulated Bearings Catalog

TFL Insulated Bearing Co., Ltd. is an ISO-certified manufacturer of insulated bearings in China. We maintain a large inventory of 1 million insulated bearings, allowing us to deliver orders within 7 days. Our product catalog includes ball bearings, angular contact bearings, spherical roller bearings, cylindrical roller bearings, needle roller bearings, tapered roller bearings, precision bearings, bushings, thrust bearings, linear bearings, single and double row bearings, and inch bearings. We also partner with leading brands like SKF, KOYO, and NTN to provide a comprehensive selection of bearings.

Customer reviews for TFL Bearings

“I’ve been working with TFL Bearings for several years now, and their products consistently exceed expectations. Eugene, their representative, has always been responsive and helpful.†— John Doe, Engineering Manager

“My team and I have seen significant improvements in machine performance since switching to TFL Bearings. Their insulated bearings are truly top-notch!†— Sarah Smith, Maintenance Supervisor

TFL Insulated Bearing Warranty

We stand behind the quality of our products and offer a warranty that reflects our commitment to customer satisfaction. At TFL, we believe in transparency and integrity, ensuring that every bearing delivered meets the highest standards. Our goal is to provide exceptional value to our customers while maintaining the lowest possible cost.

Core Technology of TFL Insulated Bearings

TFL insulated bearings are designed to prevent the passage of electric current and ensure the safety and reliability of equipment. By applying advanced ceramic coating techniques and hybrid ceramic designs, TFL bearings achieve superior insulation and durability. These bearings not only meet standard performance criteria but also offer enhanced protection against current interference.

TFL Ceramic Coating Technology: Key to Insulation Performance

Ceramic coatings are inorganic materials applied to metal surfaces to enhance their properties. These coatings consist of oxides, carbides, and nitrides, such as Al₂O₃, TiO₂, SiC, and Si₃N₄. The coating process involves techniques like fusion burning, spraying, and vapor phase deposition. TFL uses these methods to create a robust insulating layer on the bearing surface, ensuring effective current isolation.

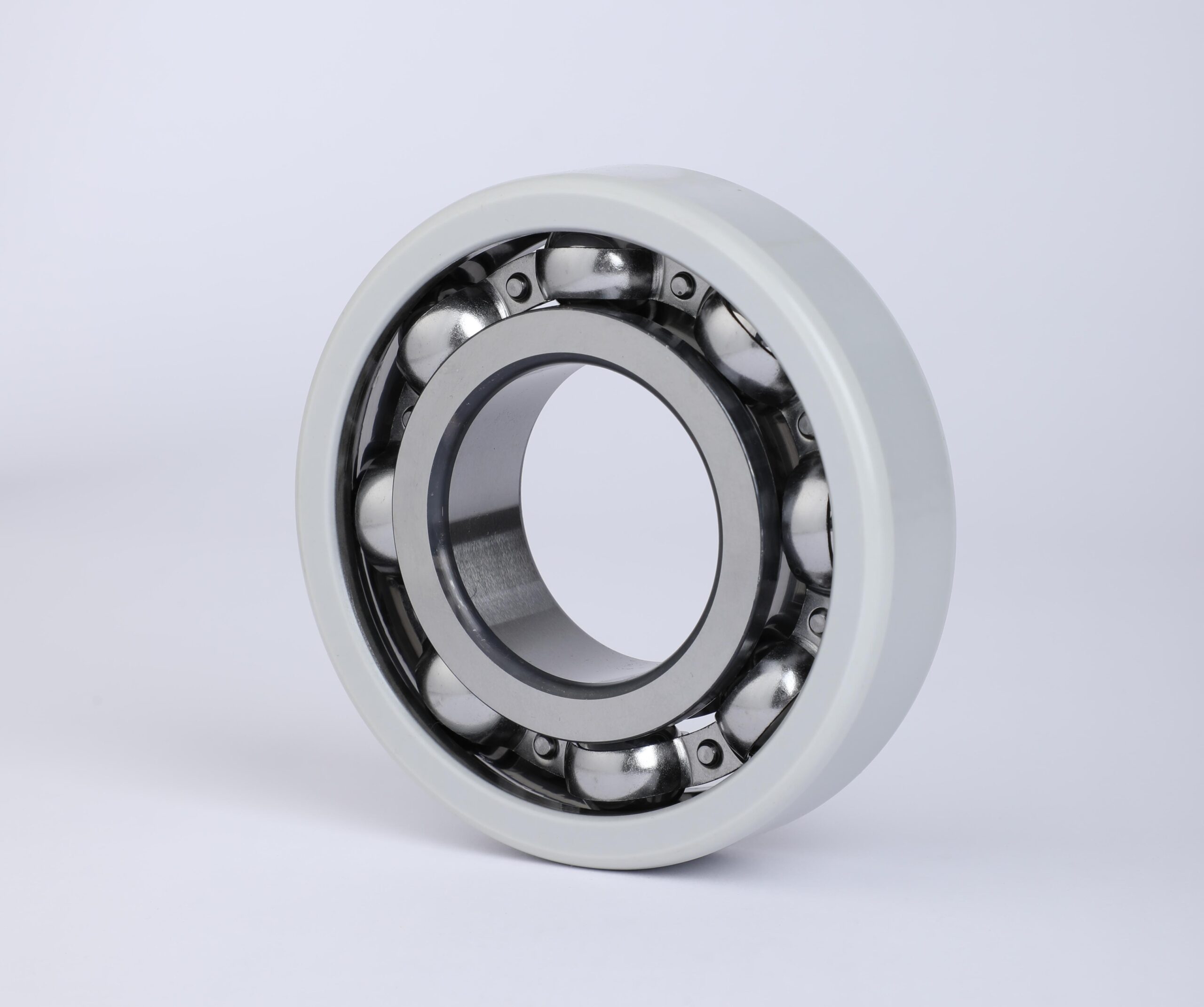

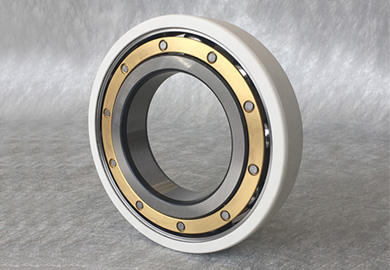

Hybrid Ceramic Design: Balancing Insulation and Durability

TFL hybrid ceramic bearings combine the benefits of ceramic rolling elements with traditional bearing designs. Key advantages include:

- Superior insulation: Protects against high voltage currents.

- Lightweight: Silicon nitride components are 60% lighter than steel, reducing centrifugal forces.

- Longer life: Reduced wear and tear, extended relubrication intervals.

- Lower friction: Enhanced performance at high speeds.

- Increased stiffness: Improved load-carrying capacity.

- Compatibility: Interchangeable with existing systems without additional tools.

Characteristics of ceramic rolling elements include excellent wear resistance, low friction coefficients, corrosion resistance, and high elastic moduli.

Optimized Dielectric Strength: Ensuring Long-term Reliable Operation

The dielectric strength of TFL insulated bearings is optimized through precise control of the coating thickness and material selection. A typical coating ranges from 50 to 200 μm, capable of withstanding voltages up to 1,000V. Thicker coatings can handle even higher voltages. The choice of materials, such as oxide ceramics, ensures both excellent insulation and corrosion resistance. Additional considerations include bond strength, heat resistance, and sealing technology to maintain durability.

Application Areas of TFL Insulated Bearings

TFL insulated bearings find application across diverse industries, including electric vehicles, wind turbines, industrial machinery, and rail transportation.

Electric Vehicles: Enhancing Powertrain Efficiency

In electric vehicles, insulated bearings protect the motor from current-induced corrosion and wear. This ensures smoother operation, longer lifespan, and improved energy efficiency. By preventing galvanic corrosion, TFL bearings contribute to the reliability of EV powertrains.

Wind Power Generation: Tackling Harsh Environment Challenges

Wind turbines rely heavily on insulated bearings to endure extreme conditions. These bearings protect critical components from high voltage surges and mechanical stress, ensuring uninterrupted operation in harsh environments. Without insulated bearings, turbines might experience frequent shutdowns due to electrical faults.

Industrial Pumps and Motors: Improving Reliability and Lifespan

Industrial pumps and motors often operate in dusty, humid, or corrosive environments. TFL insulated bearings provide enhanced protection against contamination and wear, extending the service life of these critical components. This is particularly valuable in industries like mining, oil and gas, and manufacturing.

High-speed Spindles: Reliable Partner for Precision Machining

High-speed spindles require bearings that can withstand rapid acceleration and high temperatures. TFL insulated bearings offer reliable performance in these demanding applications, protecting against current-induced damage and ensuring smooth operation.

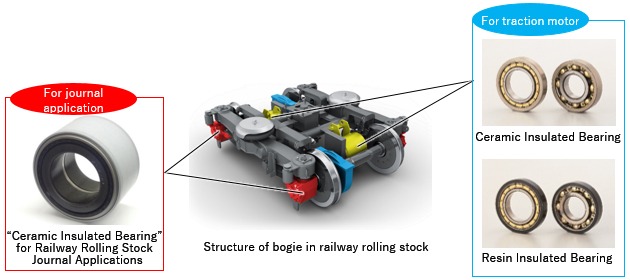

Railway Traction: Ensuring Reliability in Long-distance Transportation

In rail transport, insulated bearings are essential for protecting traction motors from electrical interference. These bearings ensure the longevity of critical components, contributing to the safe and efficient operation of trains over long distances.

Performance Advantages of TFL Insulated Bearings

TFL insulated bearings deliver exceptional performance, characterized by high load capacity, excellent temperature resistance, low noise, and extended service life. These features make them ideal for demanding industrial applications.

Excellent insulation properties: Improved equipment reliability

Insulated bearings block current flow, protecting equipment from damage caused by electrical interference. The ceramic coating provides robust insulation, preventing galvanic corrosion and extending the bearing’s service life. Si₃N₄ ceramic rolling elements exhibit excellent wear resistance and low lubrication requirements, making them ideal for high-speed and low-temperature applications.

Excellent Temperature Resistance: Adapting to Extreme Environments

Our insulated bearings are engineered to withstand high temperatures through rapid cooling and solidification of molten particles. This ensures the bearing surface remains stable at around 100°C, even under extreme conditions. This capability allows TFL bearings to operate reliably in high-voltage, high-speed motors, electric vehicles, and wind turbines.

Low Noise Operation: Enhancing Equipment Comfort

TFL insulated bearings are designed for quiet operation through optimized geometry and precision manufacturing. This minimizes noise at high speeds and improves overall equipment comfort. Additionally, the damping effect of the lubricant further reduces vibrations, contributing to quieter operation.

Extended Service Life: Reducing Maintenance Costs

The combination of advanced materials and manufacturing processes enhances the durability of TFL insulated bearings. These bearings can operate efficiently in harsh environments, minimizing downtime and repair costs. Extended service life reduces overall maintenance expenses, making them a cost-effective solution for industrial applications.

High Energy Efficiency Design: Ideal Choice for Energy Saving and Environmental Protection

TFL insulated bearings contribute to energy savings and environmental sustainability by reducing energy consumption and wear-related waste. By preventing current-induced damage, these bearings decrease maintenance needs and extend equipment life, aligning with green initiatives.

Selecting and Maintaining TFL Insulated Bearings

Proper selection and maintenance of TFL insulated bearings are crucial for maximizing their performance and lifespan.

Choosing the Right TFL Bearing Model for Your Application

When selecting TFL insulated bearings, consider the following factors:

- Insulation performance: Key metrics include insulation resistance and withstand voltage. TFL bearings typically use a plasma spray coating to achieve a 100 μm-thick insulating layer, capable of withstanding voltages up to 1,000V.

- Size and accuracy: Bearings are available in various sizes, including deep groove ball bearings (inner diameter 40–140 mm, outer diameter 80–300 mm) and angular contact bearings (inner diameter 40–140 mm).

- Load capacity and life: TFL bearings offer long-lasting performance due to their resistance to overcurrent and high reliability.

Installation Considerations: Ensuring Optimal Performance

Important installation tips include:

- Avoid direct hammering of the bearing surface during installation.

- Do not use defective insulation bearings.

- Clean the bearing chamber and bearings thoroughly, ensuring no conductive contaminants.

- Use appropriate shoulders to prevent current leakage.

- Ensure the bearing chamber has a 0.5 mm slope at a 10–15° angle.

- For DC motors, ground the shaft during resistance testing.

Daily Maintenance Tips: Extending Service Life

Regular maintenance practices include:

- Lubrication: Methods include high-pressure oil pump lubrication, circulating oil lubrication, and oil bath lubrication. Proper lubrication is essential for optimal performance.

- Cleaning and inspection: When removing bearings for inspection, photograph the exterior, record the remaining lubricant, and sample the lubricant. Use neutral solvents like diesel or kerosene for cleaning, followed by application of rust preventive oil or grease.

Performance monitoring: Timely identification of potential problems

Insulated bearings should undergo regular testing, including:

- Appearance inspection: Check for surface flatness, cracks, rust, or damage.

- Insulation performance testing: Use multimeters or insulation resistance testers to verify insulation resistance, which should exceed 100 MΩ.

- Noise testing: Measure noise levels using a sound level meter to detect loose or damaged seals.

- Lubrication testing: Assess oil levels, quality, and compatibility with the application.

Conclusion

As industrial demands grow, the importance of insulated bearings continues to rise. TFL Insulated Bearings are at the forefront of innovation, offering cutting-edge solutions for motor protection and equipment reliability. With ongoing advancements in materials and technologies, TFL bearings are poised to meet the evolving needs of modern industries. Their role in enhancing motor safety and efficiency cannot be overstated, and their market potential is vast.

Frequently Asked Questions

- What are TFL insulated bearings used for?

TFL insulated bearings are widely used in industries such as power generation, rail transport, mining, and industrial machinery. They provide critical protection against current-induced damage in electric motors and other rotating equipment.

- How do TFL insulated bearings perform in high temperatures?

These bearings are designed to handle high temperatures, thanks to their ceramic coatings and advanced materials. The coating thickness typically ranges from 50 to 200 μm, providing robust insulation against voltages up to 1,000V.

- What is the lifespan of TFL insulated bearings?

The average service life of insulated bearings is 10,000 to 25,000 hours. Factors such as operating conditions, loads, and rotational speeds significantly impact their lifespan. Proper maintenance can extend their service life considerably.

- Can I use TFL insulated bearings in outdoor applications?

Absolutely! TFL insulated bearings are well-suited for outdoor use, thanks to their robust insulating properties and ability to withstand harsh environments. They are ideal for applications involving high humidity, temperature extremes, and corrosive conditions.

- How can I contact TFL for purchases?

To purchase TFL insulated bearings, you can call us at +86 15806631151, email us at info@tflbearing.com, or visit our website at www.tflbearing.com. We also have a presence on Alibaba for easy online ordering.