Main Products and Common Welding Consumables

Our company specializes in a wide range of industrial equipment, including metallurgical machinery, port equipment, lifting systems, bulk material handling machinery, wind power components, large marine crankshafts, tunnel boring machines, low-pressure steam turbine casings, and generator units. During the manufacturing process, we use various welding consumables, which are detailed in the attached table and figures (Figure 1 and Figure 2).

Welding Material Application Case and Solution

In our daily production, one of the main challenges we face is selecting the right welding consumables for specific material requirements. The key issue arises after annealing or normalizing, where the impact energy of both the weld metal and heat-affected zone fails to meet low-temperature impact standards.

(1) **Project Overview**: We produced a ring welding flange with dimensions of 160mm × φ4000mm / φ3650mm. The flange material was Q345-E, and over 70 pieces were manufactured. After welding, the flanges underwent normalization, and mechanical testing was performed. The required impact energy at -40°C needed to be ≥16J.

(2) **Challenges Faced**: Multiple welding wires were tested, including ER50-6, ER50-G, TWE-711, TWE-711Ni, HS09MnDR, and H10Mn2. However, after normalization, the impact values at -40°C did not meet the required specifications.

(3) **Solution Implemented**: We tested the HS09MnNiDR welding wire from Ha Welding Station. After normalization, the test samples met the required impact energy levels at -40°C. This wire was ultimately selected for production, although it was significantly more expensive—over five times the original budget.

(4) **Test Summary**: As shown in Figure 3, our testing revealed that the heat treatment temperature directly affects the impact properties of the welding materials. Higher heat treatment temperatures generally result in lower impact values.

Expectations and Suggestions for Future Development of Welding Consumables

(1) **Research on Different Heat Treatment Conditions**: Many structural products require post-welding heat treatments such as annealing, stress relief, tempering, or normalizing. It would be beneficial if welding material manufacturers could conduct studies under various heat treatment conditions to better meet the needs of different applications.

(2) **Development of High-Strength Steel Welding Consumables**: Currently, when it comes to high-strength steel welding like Weldox 960, only imported welding consumables are available, which leads to high costs and long lead times. We hope domestic manufacturers will invest more in research and development to create mature solutions for high-strength steel welding. Additionally, there are many ongoing studies in China on heat-resistant, low-temperature, corrosion-resistant, and stainless steel wires, which shows promising potential for future growth.

More exciting content: Welcome to Metalworking Online》》》Essen Special Report

The 19th Beijing Essen Welding & Cutting Fair

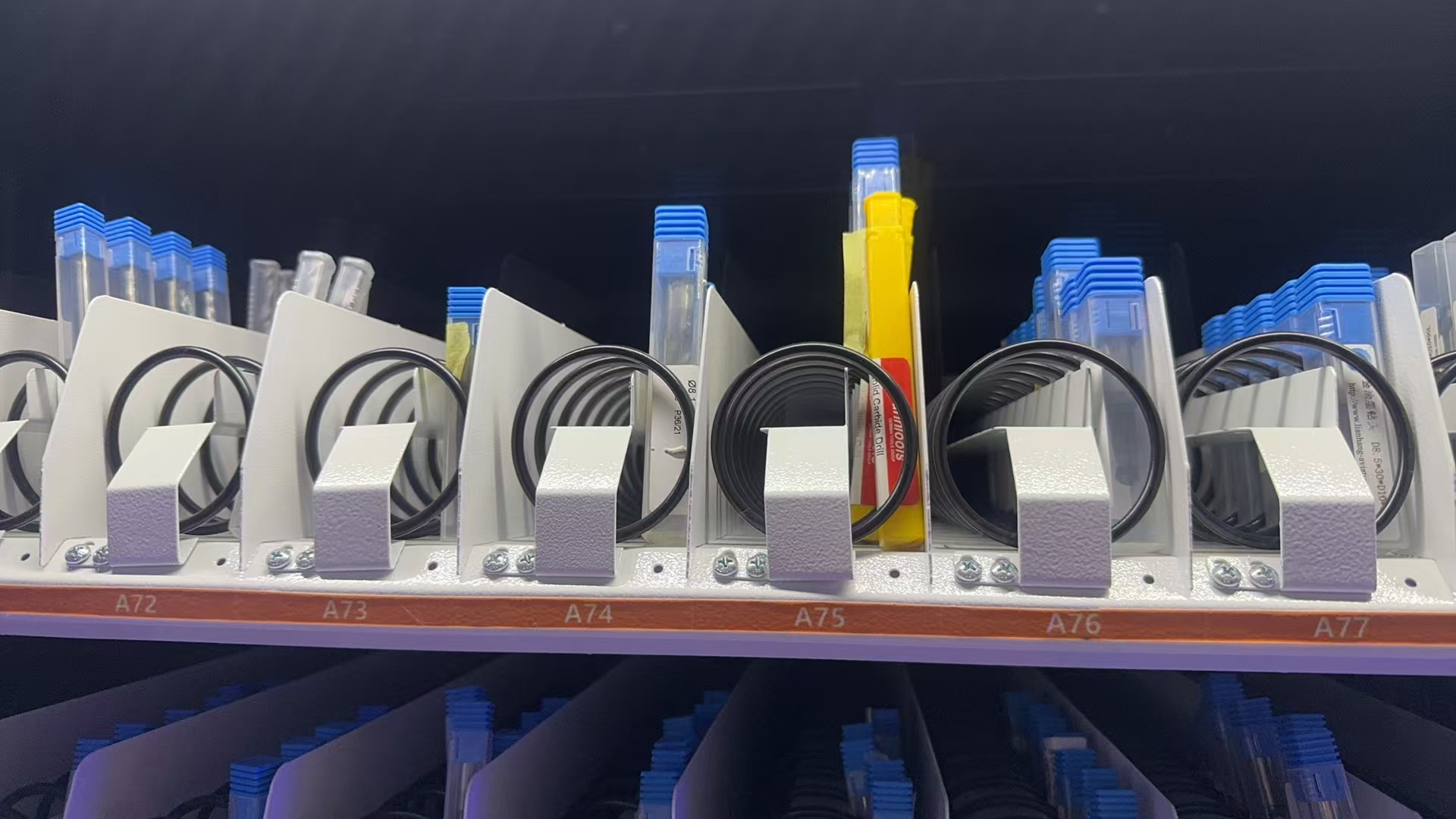

Spring Coil Cabinets

Spring Coil Cabinets

Ideal for dispensing boxed or small packaged items such as cutting tools, gloves, or inserts.

This smart cabinet integrates spring coils and grid compartments with a vertical lifting platform, designed to store and manage various boxed tools, inserts, gloves, and small components. The lift system automatically brings the selected tray to the access window, making it easy and ergonomic for users to retrieve items.

The cabinet supports user authentication (RFID, code, face), real-time inventory tracking, and automatic refill reminders. With flexible configurations and a compact footprint, it’s ideal for tool rooms, CNC workshops, and production lines.

Applications:

CNC tool storage, consumable management, workshop automation, tool distributors.

Features:

Compact design, mixed storage modes, lifting platform, smart access control, customizable layout.

Intelligent Cnc Tool Storage Cabinet,Wooden Drawer Cabinet,Intelligent Equipment Management Cabinets

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com