Main Products and Common Welding Consumables

Our company specializes in a wide range of industrial equipment, including metallurgical machinery, port handling systems, lifting devices, bulk material handling solutions, wind power components, large marine crankshafts, tunnel boring machines, low-pressure steam turbine casings, and generator units. During the manufacturing process, we use various welding consumables to ensure high-quality welds. A detailed list of these commonly used materials is provided in the attached table, as well as in Figure 1 and Figure 2.

Welding Material Application Case and Solution

In our daily operations, one of the main challenges related to welding consumables is selecting the right materials for special applications. Specifically, after annealing or normalizing, the impact energy of both the weld metal and heat-affected zone often fails to meet the required standards at low temperatures.

(1) Project Overview: We recently worked on a large ring welding flange with dimensions of 160mm × φ4000mm / φ3650mm. The flange material used was Q345-E, and we produced over 70 pieces. After welding, the flanges were normalized, and mechanical testing was conducted. The requirement was that the impact energy at -40°C should be at least 16J.

(2) Challenges Faced: Several types of welding wires were tested, including ER50-6, ER50-G, TWE-711, TWE-711Ni, HS09MnDR, and H10Mn2. However, after normalization, the samples failed to meet the low-temperature impact requirements.

(3) Solution Implemented: We finally tested the HS09MnNiDR welding wire (from Ha Welding Station). After normalization, the test specimens met the required impact energy at -40°C. Although this wire is significantly more expensive—over five times the budget—it was ultimately chosen for production.

(4) Test Summary: As shown in Figure 3, after conducting multiple tests, we found that the heat treatment temperature directly affects the impact properties of the welding material. Higher heat treatment temperatures tend to reduce the impact value.

Expectations and Suggestions for Future Development of Welding Consumables

(1) Experimental Research on Different Heat Treatment Conditions: Many structural products require post-weld heat treatments such as annealing, stress relief, tempering, or normalizing. It would be beneficial if welding material manufacturers could conduct more research under varying heat treatment conditions to better suit different application needs.

(2) Development of High-Strength Steel Welding Consumables: Currently, when it comes to high-strength steel welding, such as Weldox 960, only imported welding consumables are available. This leads to high costs and long lead times. It is hoped that domestic manufacturers will invest more in developing mature, high-performance welding materials for such applications. Additionally, there is ongoing research in areas like heat-resistant steels, low-temperature steels, corrosion-resistant steels, and stainless steel wires.

More exciting content: Welcome to Metalworking Online》》》Essen Special Report

The 19th Beijing Essen Welding & Cutting Fair

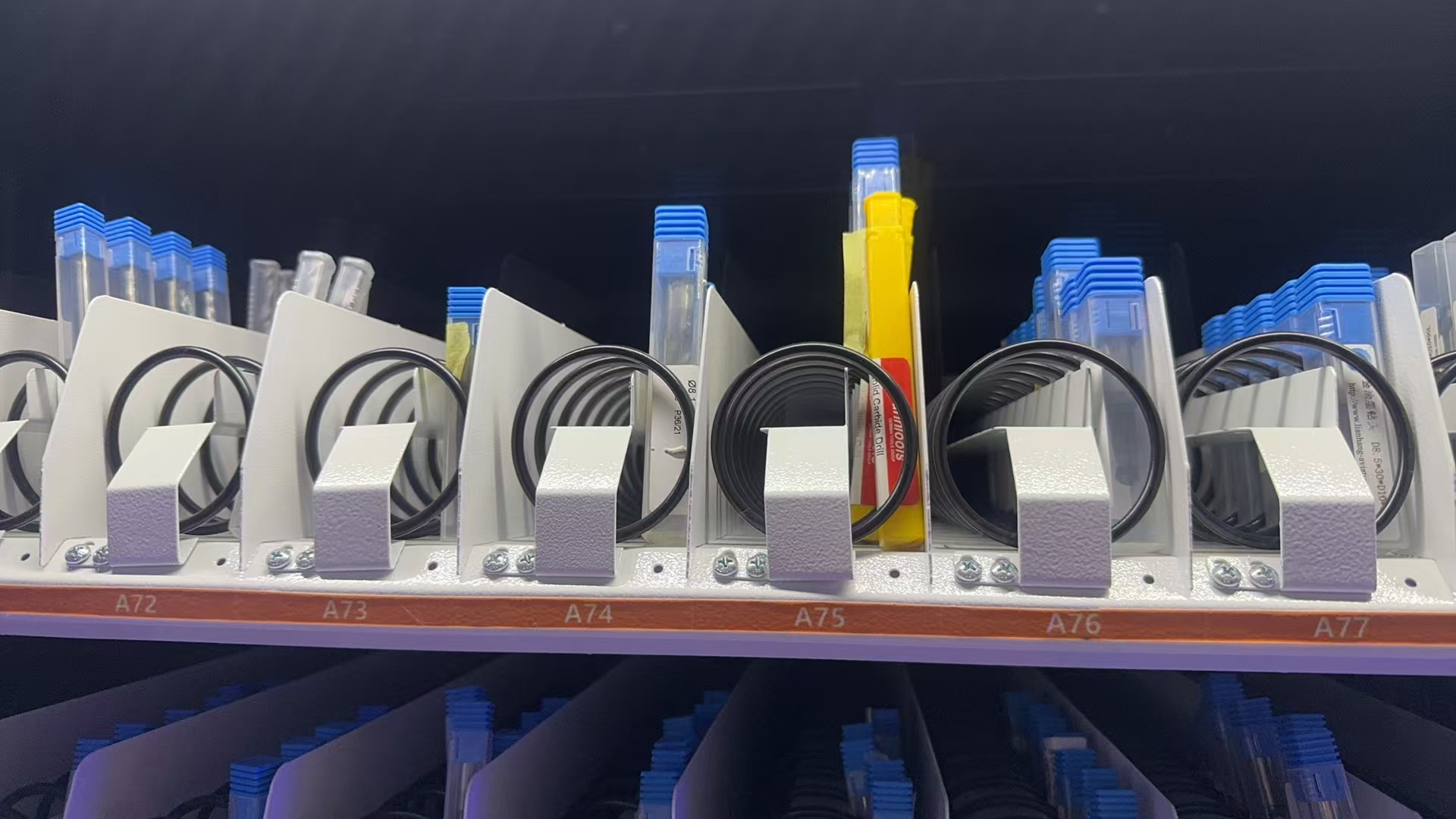

Dual Access Smart Coil & Grid Cabinet

Two dispensing ports for faster, smarter tool distribution

This cabinet combines spring coils and grid compartments with dual access windows, allowing two users to pick up items at the same time. It improves efficiency in busy workshops while maintaining full control over access and inventory.

Each side can be configured independently, supporting different item types such as boxed cutting tools, inserts, gloves, or small parts. With smart access control (RFID, face, code), real-time inventory tracking, and modular design, it’s ideal for factories with high tool turnover.

Applications:

CNC workshops, toolrooms, consumable management in production lines.

Highlights:

Dual user access, mixed storage modes, fast tool dispensing, customizable layout, real-time tracking.

Intelligent Workside Tool Cabinet,Intelligent Tool Handle Management Cabinet,Intelligent Labor Protection Equipment Management Cabinet,Intelligent Tool Management Cabinet

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com